Key Features:

◆ Suitable for loading and unloading of hollow lines and laminated lines, and for handling of raw sheets and unit plates. It is widely used in the glass deep processing industry;

◆ Suitable for high-altitude glass installation, maximum load 3000KG, other requirements can also be customized;

◆ A variety of structures and suction cup materials are available;

◆ It can realize 0-90 degree flipping of glass in vertical direction and 360 degree rotation and transportation in horizontal direction;

◆ The suction cup position can be adjusted, and any suction cup can be started or stopped individually;

◆ One person can operate it easily;

◆ Efficient, safe, fast and labor-saving;

◆ Remote controller can be configured

Product Details:

| model | load | Suction cup size | Number of suction cups | Power supply | Rotation function | Flip function | Weight(KG) | Dimensions (mm) | |

| Portable | GS-300 | 300KG | 300MM | 3 | 12V | / | / | 33.1 | 900*560*200 |

| GS-400 | 400KG | 4 | 37 | 980*650*200 | |||||

| GS-500 | 600KG | 6 | 41 | 1160*650*200 | |||||

| Long | GL-400 | 400KG | 4 | 0~360° | 0~90° | 70 | 1200*700*280 | ||

| GL-600 | 600KG | 6 | 77 | 1200*700*280 | |||||

| Intelligent | GM-400 | 400KG | 4 | 88.8 | 895*895*350 | ||||

| GM-600 | 600KG | 6 | 101.9 | 1250*1250*350 | |||||

| GM-800 | 800KG | 8 | 115.5 | 2350*2350*350 | |||||

| GM-1000 | 1000KG | 10 | 129.1 | 3000*2350*350 | |||||

| GM-1200 | 1200KG | 12 | 153.6 | 3000*3000*350 | |||||

| GM-1400 | 1400KG | 14 | 168 | 3350*3000*350 | |||||

| GM-1600 | 1600KG | 16 | 185 | 3700*3000*350 | |||||

| GM2000 | 2000KG | 20 | 201 | 4000*3000*350 |

Key Features:

◆ Can be used for loading and unloading of laser cutting machines, plasma cutting machines, and shearing machines;

◆ Can be used as a fixture and integrated on a manipulator or articulated robot;

◆ Mainly used for non-magnetic materials such as stainless steel plates and marble plates;

◆ Imported vacuum pumps and valves;

◆ Load ranges from 300 to 2000KG;

◆ Accumulator and pressure detection alarm prompts to ensure safe operation;

◆ The position and size of the suction cup can be adjusted, and the material and shape of the suction cup can be customized;

◆ One person can operate it easily;

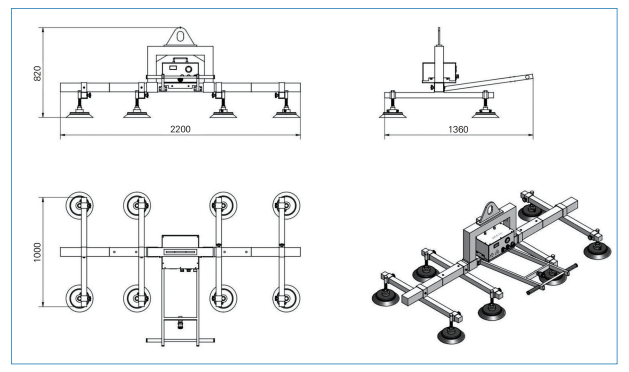

Product Details:

| model | load | Suction cup size | Number of suction cups | Power supply | Weight(KG) | Dimensions (mm) | |

| Pneumatic | GQ-300 | 300KG | 150MM 200MM Other customized | 6 | Compressed air | 53.7 | 2000*1300*650 |

| GQ-400 | 400KG | 68 | |||||

| Plug-in | GE-300 | 300KG | 220V/380V power supply | 59 | |||

| GE-400 | 400KG | 69.5 | |||||

| GE-600 | 600KG | 82.6 | 3000*1500*650 | ||||

| GE-800 | 800KG | 8 | 91.5 | ||||

| GE-1000 | 1000KG | 10 | 101 | 5000*1500*650 | |||

| GE-1200 | 1200KG | 12 | 109 | ||||

| GE-1400 | 1400KG | 14 | 118 | ||||

| GE-1600 | 1600KG | 16 | 125 | ||||

| GE-2000 | 2000KG | 20 | 132 | 6000*1500*650 | |||

| Charging model | GX-300 | 300KG | 6 | 12V battery | 67 | 2000*1300*650 | |

| GX-400 | 400KG | 72 | |||||

| GX-600 | 600KG | 84.5 | 3000*1500*650 | ||||

| GX-800 | 800KG | 8 | 100.5 | ||||

| GX-1000 | 1000KG | 10 | 107 | 5000*1500*650 | |||

| GX-1200 | 1200KG | 12 | 114 | ||||

| GX-1400 | 1400KG | 14 | 121 | ||||

| GX-1600 | 1600KG | 16 | 129 | ||||

| GX-2000 | 2000KG | 20 | 136 | 6000*1500*650 |

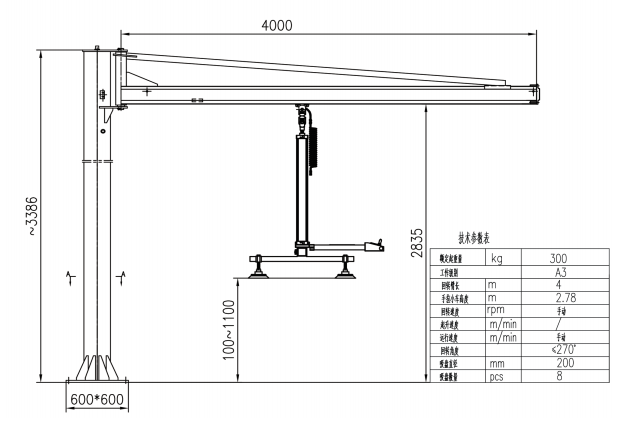

Product structure:

Key Features:

◆?Easy to operate and stable in operation. The operator only needs to apply a small amount of force to lift, lower and carry the load at will, and can operate freely in three-dimensional space;

◆??No physical limitation on the operator, which can reduce labor intensity, improve work efficiency and work safety?;

◆??Mature technology, stable performance, long life, strong maintenance-free capability?;

◆??Equipped with safety protection device. When the gas source is suddenly interrupted or the pipeline bursts, the load will slowly drop to avoid accidents?;

◆??Using compressed air as energy source, energy saving and environmental protection; can be used in explosion-proof environment?;

◆??Manual lifting and feeding, good repeatability, the hand lever valve uses the original imported manual valve to control the lifting and lowering, precise control in place?;

◆??The material picking method adopts vacuum suction, which has fast suction speed, good stability, small vibration and long service life. The movable suction cup controls the size of the suction plate area?;

Product parameters:

| Product Model | Rated load | Cylinder stroke (mm) | Cylinder bore (mm) | Lifting height(mm) | Radius of rotation | Wing span(m) | Suction cup diameter (mm) | Number of suction cups | Sheet size (mm) |

| YB-100 | 100KG | 1000 | 63 | 1100 | 270° | 3/4 meter | 100 | 8 | 3000*1500 |

| YB-300 | 300KG | 100 | 150 | ||||||

| YB-500 | 400KG | 1250 | 125 | 300 |

Product structure:

Intelligent hoists are widely used?in the precise assembly of parts at various stations in the production lines of machinery, automobiles, home appliances and other industries. They are mainly used to reduce the workload of production line personnel and improve work efficiency.

The main uses are: material handling, component installation, mold replacement, mechanical processing and manufacturing, automobile assembly lines, and precision equipment maintenance.

- ?Characteristics of intelligent hoist

- ?Free speed control: The intelligent auxiliary lifting equipment can move synchronously with the operator and can move at the speed selected by the operator, which can be fast or slow, making it very suitable for operating environments where a load sometimes requires high speed operation and sometimes requires slow and precise operation.

- ?Millimeter-level accuracy: It can achieve a lifting speed of less than?0.3?meters?per?minute, thereby ensuring the precise positioning requirements of production line production personnel.

- ?Safe choice: Zhitong auxiliary lifting equipment is safe and reliable, which greatly reduces the occurrence of work-related accidents.

- ?Anti-rebound technology: This technology can prevent the lifting equipment from deflecting or rebounding when the load weight changes, thereby reducing potential injury accidents.

- ?Overload protection: When the load exceeds its rated lifting weight, the lifting equipment will automatically protect itself and cannot be lifted.

- ?Operator in place function: The sliding handle of Zhitong lifting equipment has a built-in photoelectric sensor, which will not allow the equipment to operate unless the operator issues an operating instruction.

- ?Suspension mode function: The equipment is equipped with a multi-purpose “suspension mode”. By simply applying a?2KG?force to the load, the operator can control the load with both hands and accurately position it within the entire range.

- ?Suspension unloading mode function: The lifting equipment is equipped with a “suspension unloading mode” specifically for unloading objects. The operator can control the load with both hands to achieve precise unloading.

- ?High cost performance: Intelligent auxiliary lifting equipment technology greatly improves factory production efficiency by improving workers’ labor efficiency and assisting in completing complex tasks.

- ?Description of the main components of the intelligent hoist

The intelligent hoist is mainly composed of a servo drive?,?a servo motor?,?a reducer?,?sensors and related structural parts.

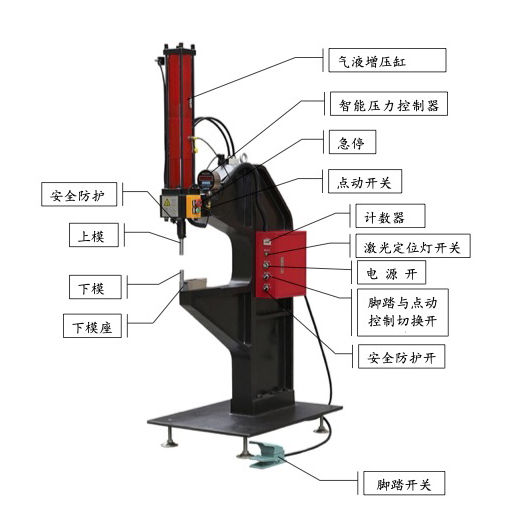

]]>A riveting machine is a mechanical device used to perform riveting operations. Riveting is a method of permanently joining two or more workpieces together by forming rivets or studs on the workpieces. The riveting machine forms and presses the rivets or studs onto the workpieces by applying pressure, thus forming a secure connection. This method of joining is commonly used to join metal workpieces, providing a reliable mechanical connection without the use of welding or bolts.

Key Features:

◆ Powerful pressure system: Riveting machines are usually equipped with powerful hydraulic or pneumatic systems that can provide enough force to form a strong riveted connection;

◆ Punch (die) design: The punch is a tool used to apply pressure and form rivets or rivet studs. Its design depends on the type of riveting required and the characteristics of the workpiece, and it is usually replaceable to adapt to different workpieces;

◆ Versatility: Some riveting machines have a multifunctional design that can adapt to workpieces of different shapes and sizes, as well as perform different types of riveting operations, such as blind riveting, squeeze riveting, etc.;

◆ Accurate control system: Modern riveting machines are usually equipped with advanced control systems, which ensure the accuracy and repeatability of operations through programming or automated control;

◆ Safety system: Riveting machines are usually equipped with safety systems, including emergency stop buttons, protective covers, etc., to ensure the safety of operators and equipment;

◆ Workbench and positioning system: The workbench of the riveting machine is used to support and position the workpiece, and usually has an adjustable function to accommodate workpieces of different sizes and shapes;

◆ Sturdy machine tool structure: In order to maintain stability under high pressure and high load, the machine tool structure of the riveting machine is usually designed to be sturdy;

◆ Multi-material applicability: Riveting machines are usually suitable for a variety of materials, including metals and plastics, to meet the needs of different industrial fields;

◆ High degree of automation: Some riveting machines have automation functions and can be integrated into the production line to achieve a highly automated production process;

◆ Easy to maintain: The design focuses on easy maintainability, facilitating daily maintenance and repair to ensure the stability and reliability of the equipment;

Product parameters:

| Product Model | YY6-500C | YY8-500C | YY10-500C | QY5-500C | QY8-500C |

| Drive Mode | Fully hydraulic | Pneumatic (3-6bar) | |||

| Output pressure range | 0.5-6T | 0.5-8T | 0.5-10T | 0.5-5T | 0.5-8T |

| Throat depth | 500mm | ||||

| Safety protection | Random standard | Standard | |||

| Hard limit | / | ||||

| Motor power | 2.2KW | 3.75KW | 5KW | / | |

| Equipment weight | 490KG | 520KG | 560KG | 480KG | 500KG |

| Pressure repeatability | ±1% | ||||

| Holding time | 1~5s | ||||

| Pressing rate | 65mm/s | 100mm/s | |||

| Throat height | 380mm | 365mm | |||

| Laser light assisted positioning | Optional | Optional/Standard | |||

| Voltage | 220V | ||||

| External network size | 1070mm×650mm×1695mm | 1070mm×650mm×2095mm | |||

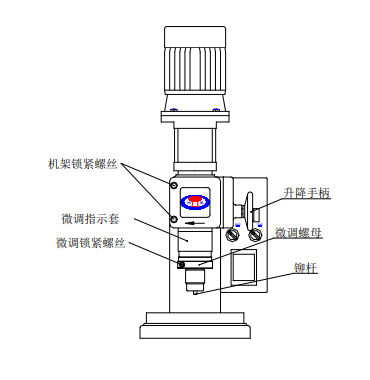

Product structure:

The operation process of the riveting machine usually includes the following steps:

- Positioning the workpiece: Place the workpiece to be riveted accurately on the workbench.

- Choose the right punch and rivet: Choose the appropriate type and size of punch and rivet based on the workpiece requirements and design specifications.

- Adjust machine parameters: Adjust the pressure, stroke and other parameters of the riveting machine according to the characteristics and requirements of the workpiece.

- Pressing operation: Start the riveting machine so that the press head applies sufficient pressure to form the rivet and connect the workpieces.

- Check the quality of the connection: Check the quality of the riveted connection to ensure it meets the design and quality standards.

Presses are widely used in the manufacturing industry, especially in automotive manufacturing, aerospace, electronics and other industries that require high-strength connections. Different types of presses are used for different sizes and types of riveting tasks.

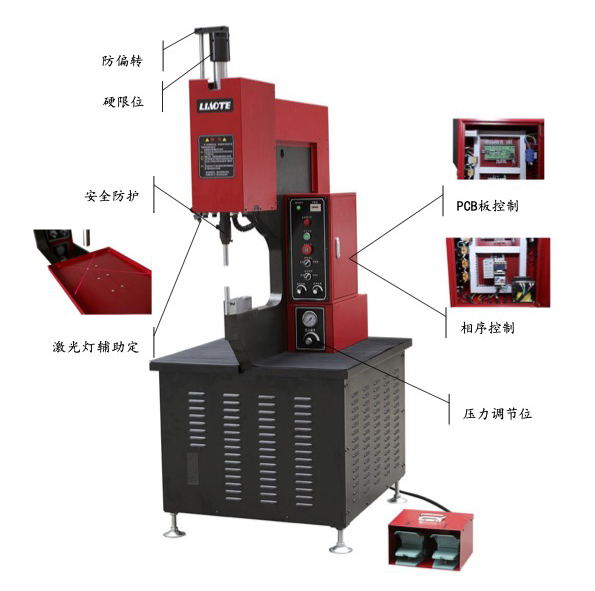

]]>This machine is fully functional. According to the different designs of the rivet rod, it can rivet countersunk, semi-circular, cylindrical, spherical cylindrical rivets and hollow rivets. It can also use the rotating extrusion of the rivet rod to squeeze the concave countersunk platform to make the platform surface bright. The advanced circuit design can realize the automatic action of riveting, ensure the consistency of the riveting time each time, and improve the qualified rate of products. When using automatic operation, the timer can be adjusted to the most suitable time at will, which greatly improves the production efficiency and controls the output of the shift, reducing human loss.

This machine has a wide range of uses and is suitable for recording movements, cameras, clocks, radio components, hardware, steel and wood furniture, shutters and all areas that require riveting. It is a popular hardware machine in developed countries.

Key Features:

1. Low noise: Due to the use of rotary pneumatic transmission and the installation of a muffler, there is no noise pollution; the lubricating oil mixture is discharged from the rear of the machine, so there is no harm to the human body.

2. Simple operation: just step on the foot switch to start riveting automatically.

3. Short riveting time: For example, it only takes 0.3 seconds to process a ψ3mm rivet.

4. Good processing quality: Due to the use of special mechanism, the riveting surface is smooth and accurate, and the riveted rivets will not be roughened or deformed.

5. Wide range of applications: Different rivet head types can be riveted by changing the rivet rod (as shown in Figure 1).

Technical parameters:

| Model | HD?-132 | HD?-136 | HD?-141 | HD-?141A | HD?-143 | HD?-143A | HD-?150 | HD-?152 | HD-?155 | |

| Motor (Oil Pump Motor) | 1/4HP | 1/4HP | 1/2HP | 1/2HP | 1HP | 1HP | 1?×?2HP | 1?×?2HP | 2?×?3HP | |

| Spindle travel | 25mm | 35mm | 40mm | 40mm | 40mm | 40mm | 40mm | 40mm | 40mm | |

| Rivet Capacity?(Mild Steel) | solid | 0.3?—?3 | 0.5?—?4 | 1?—?7 | 1?—?7 | 2?—?9 | 0.5?—?5 | 3?—?12 | 3?—?12 | 3?—?25 |

| Hollow | 1?—?6 | 1?—?8 | 1?—?15 | 1?—?15 | 1?—?20 | 1?—?9 | 3?—?25 | 3?—?25 | 3?—?40 | |

| Time adjustment (seconds) | 0.5?—?10 | 0.5?—?10 | 0.5?—?10 | 0.5?—?10 | 0.5?—?10 | 0.5?—?10 | 0.5?—?10 | 0.5?—?10 | 0.5?—?10 | |

| Use pressure | 1?—?6 | 1?—?7 | 2?—?7 | 2?—?7 | 3?—?7 | 3?—?7 | 20?—?70 | 20?—?70 | 20?—?100 | |

| Maximum pressure | 100-480 | 70-700 | 230-800 | 230-800 | 460-?1100 | 460-?1100 | 430-1650?? | 430-1650?? | 1400-5500 | |

| Mechanical height (adjustable) | 680 | 790-890 | 940-?1050 | 1050-1170?? | 1150-1220?? | 1050-1220?? | 1750 | 1600 | 2000 | |

| Rivet length (maximum) | 100 | 100 | 150 | 280 | 200 | 150 | 180 | 230 | 300 | |

| Throat depth | 90 | 105 | 120 | 120 | 125 | 125 | 170 | 160 | 200 | |

| Rivet head speed | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | |

| Maximum working surface | 150?×?250 | 180?×?250 | 190?×?320 | 190?×?320 | 190?×?320 | 190?×?320 | 190?×?320 | 140?×?240 | 160?×?260 | |

| Weight (kg) | 50 | 80 | 120 | 128 | 170 | 180 | 300 | 350 | 450 | |

| Dual axis distance (adjustable) | 35-?150 | |||||||||

Product structure:

The rigid arm power manipulator has a wide range of uses and is mainly used in the following areas:

- Automobile manufacturing industry: used to transport and assemble automobile parts, such as engines, gearboxes, doors, etc., to ensure the accuracy and safety of the installation process.

- Mechanical processing industry: used in the process of loading and unloading materials and transferring workpieces, it can improve work efficiency and reduce the labor intensity of workers.

- Electronic and electrical industry: suitable for handling and assembling electronic components, electrical housings, etc. to avoid damage from static electricity and collision.

- Food and beverage industry: used for handling and assembling food processing equipment, beverage filling equipment, etc., to meet hygiene and safety requirements.

- Pharmaceutical industry: used in the process of drug production and packaging to ensure the sterility and safety of drugs.

- Chemical industry: suitable for handling and assembling chemical equipment, chemical reagents, etc. to prevent leakage of dangerous goods and personal injury.

- Logistics and warehousing industry: used in the handling, stacking, sorting and other links of goods to improve logistics efficiency and safety.

- Aerospace industry: used to handle and assemble aerospace parts, ensuring high precision and high safety.

The use of rigid-arm assisted manipulators can not only improve production efficiency and reduce workers’ labor intensity, but also effectively prevent workpieces from being damaged during handling and assembly, thereby improving product quality and consistency.

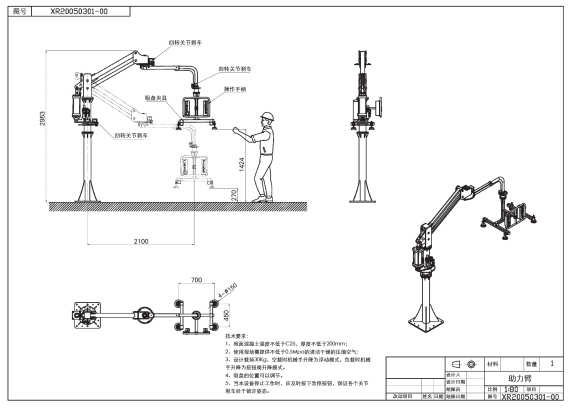

Product Structure

Product Parameters

| Product Model | HAC-BS100 | HAC-BS200 | HAC-BS300 |

|---|---|---|---|

| Rated load(KG) | 100 | 200 | 300 |

| Working radius (L) | 2500 | 2500 | 2500 |

| Lifting height(H) | 1500 | 1500 | 1500 |

| Air source pressure (P) | 0.5mpa | 0.5mpa | 0.5mpa |

| Rotation angle (A) | 330° | 330° | 330° |

| Rotation angle (B) | 300° | 300° | 300° |

| Rotation angle (C) | 360° | 360° | 360° |

The soft-cable power manipulator combines sophisticated mechanical motion design with simple pneumatic control, and has the characteristics of easy operation, fast speed and full suspension. Its lifting function is achieved by the movable pulley cylinder pulling the soft cable to drive the sling to rise. Compared with the hard-arm power manipulator, it can achieve a larger lifting stroke under the same height limit. Therefore, the soft-cable power manipulator is widely used in scenes with light workpiece weight, simple transplanting process, non-eccentric operation, large lifting stroke and fast operation rhythm.

Installation

1. Rigid arm column installation

- Scope of application?: Suitable for working conditions where the center of gravity is far away from the cantilever hanging point, or where the workpiece needs to be flipped and tilted.

- Features?: stable structure, strong load-bearing capacity, suitable for complex operation requirements.

2. Mobile installation

- Scope of application?: Suitable for occasions requiring flexible mobile operations, usually installed on a mobile trolley.

- Features?: Easy to move, wide adaptability, and able to meet the needs of changing working environments.

Features

- Large lifting stroke

- The maximum lifting stroke can reach 2 meters, which is particularly beneficial for the handling and transplanting of high-position products and improves work efficiency.

- Flexible operation

- It adopts wire rope lifting, and the operating balance force is less than 3KG, so the operator can easily complete various operations.

- The rotating joint is designed to be flexible and can meet the needs of multi-angle and multi-directional operation.

- Wide working radius

- The standard working radius reaches 3 meters, covering a larger working range and adapting to a variety of working environments.

- Convenient pneumatic control

- All operation buttons are concentrated in the handle control box, supporting one-handed operation, simplifying the operation process and improving work efficiency.

- Unique lifting mechanism

- The cylinder or pneumatic balance hoist inside the boom is used to tighten the wire rope to achieve smooth and efficient lifting operations.

Gas circuit features

- Gas cut-off protection device

- When the gas source is accidentally interrupted, the equipment can remain in a non-falling state, ensuring the safe completion of the current process and protecting the safety of operators and equipment.

- Working pressure display

- Real-time display of working pressure status facilitates operators to monitor equipment operation, promptly identify and eliminate potential risks, and reduce operational risks.

- Brake safety device

- Prevent the equipment from accidentally rotating due to external forces and ensure the stability and safety of the operation process.

- Fully balanced unit

- Realize weightless operation, improve the accuracy and stability of equipment movement, and reduce the labor intensity of operators.

With its outstanding design and excellent performance, the soft-cable assisted manipulator has become an ideal choice for light workpiece handling and assembly in various industries, greatly improving production efficiency, reducing labor costs, and ensuring operational safety.

| Specifications | SAC-RS100 | SAC-RS200 | SAC-RS300 |

|---|---|---|---|

| Maximum load(KG) | 100 | 200 | 300 |

| Height travel (H) | 1500 | 1500 | 1500 |

| Increase the upper limit (H) | 1600 | 1600 | 1600 |

| Maximum working radius 1 (R1) | 500 | 500 | 500 |

| Maximum working radius 2 (R2) | 2500 | 2500 | 2500 |

| Minimum air source pressure (P) | 0.5mpa | 0.5mpa | 0.5mpa |

| Machine weight(KG) | 270 | 300 | 350 |